CNC Tapping

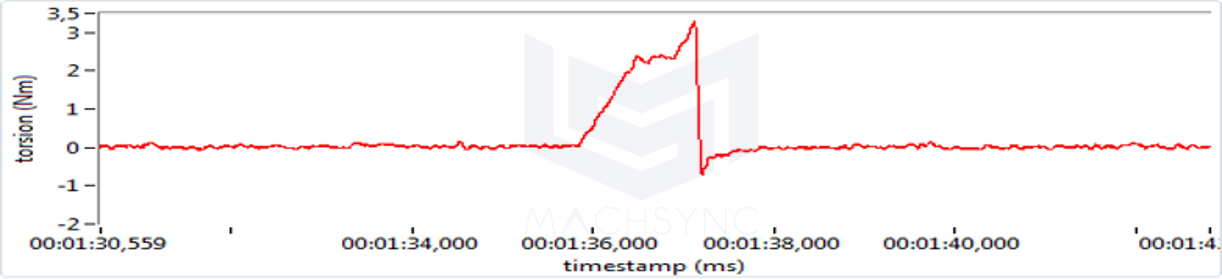

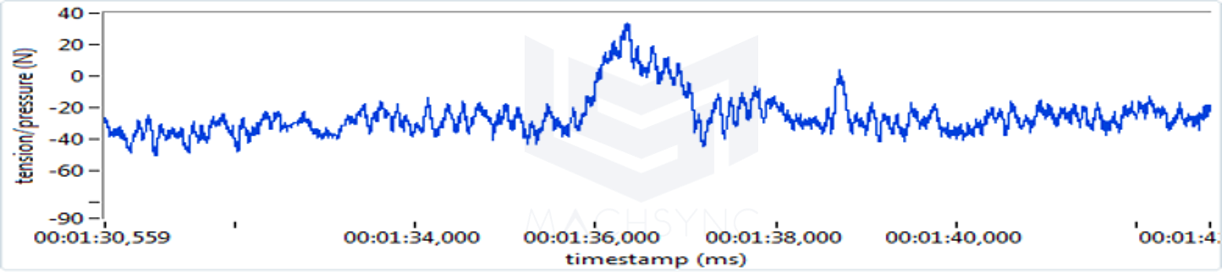

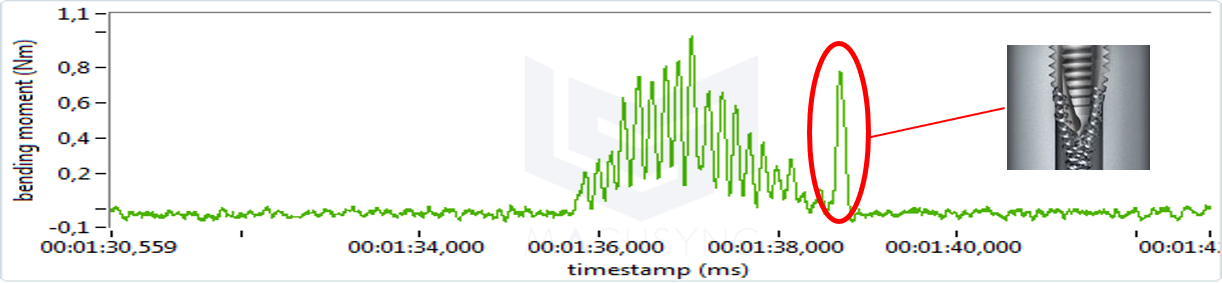

Tapping refers to threading the inner wall of the hole and making threads so that the corresponding bolts or screws can be connected to it. CNC tapping has always been a complex process that is difficult to detect quality. It tests the synchronization and matching between motors, and the matching between parameters and tapping thread cutting tool is also very demanding, not to mention the overall accuracy and the quality after processing. Verification is very difficult. For decades, quality inspection has always been the soil method of using bolts to directly test the locking. As for whether the locking of the teeth holes is smooth, whether there is skew, whether the threads have large or small edges or the detection of chip squeezing in the holes under the tapped holes. Most of them require a lot of manpower for quality control to detect, and at this time, you can control the quality through real-time sensing of the "smart tool holder".